Inspection equipment

High-End-Technik for traceable quality

Professional results require professional equipment.

Thor Engineering Services & Expert Office GmbH relies on state–of-the-art technology for carrying out all inspection work - mobile, documented in high resolution and optimally tailored to industrial requirements in the areas of pipeline construction, tank systems and apparatus construction. Apparatebau Our systems offer not only visual inspection – they provide digital verification at the highest level.

→ VUMAN E3+

High-resolution camera unit for image-guided inspections in confined or sensitive plant areas

4K Ultra HD resolution for single photo and video

For hygienically demanding locations (pharmaceuticals, food, ultrapure media)

Real-time evaluation with direct image storage

Ideal for internal inspections of weld seams and joints

→ SNK Ultra 365

Modular video endoscope for pipeline and vessel inspections with flexible optics guidance

REVOLVER® technology with 4-way swivel head

Probe lengths of up to 30 m - ideal for larger systems like pressure vessels and tank facilities

Integrated recording and commenting system

Use in new facilities, revisions, GMP applications

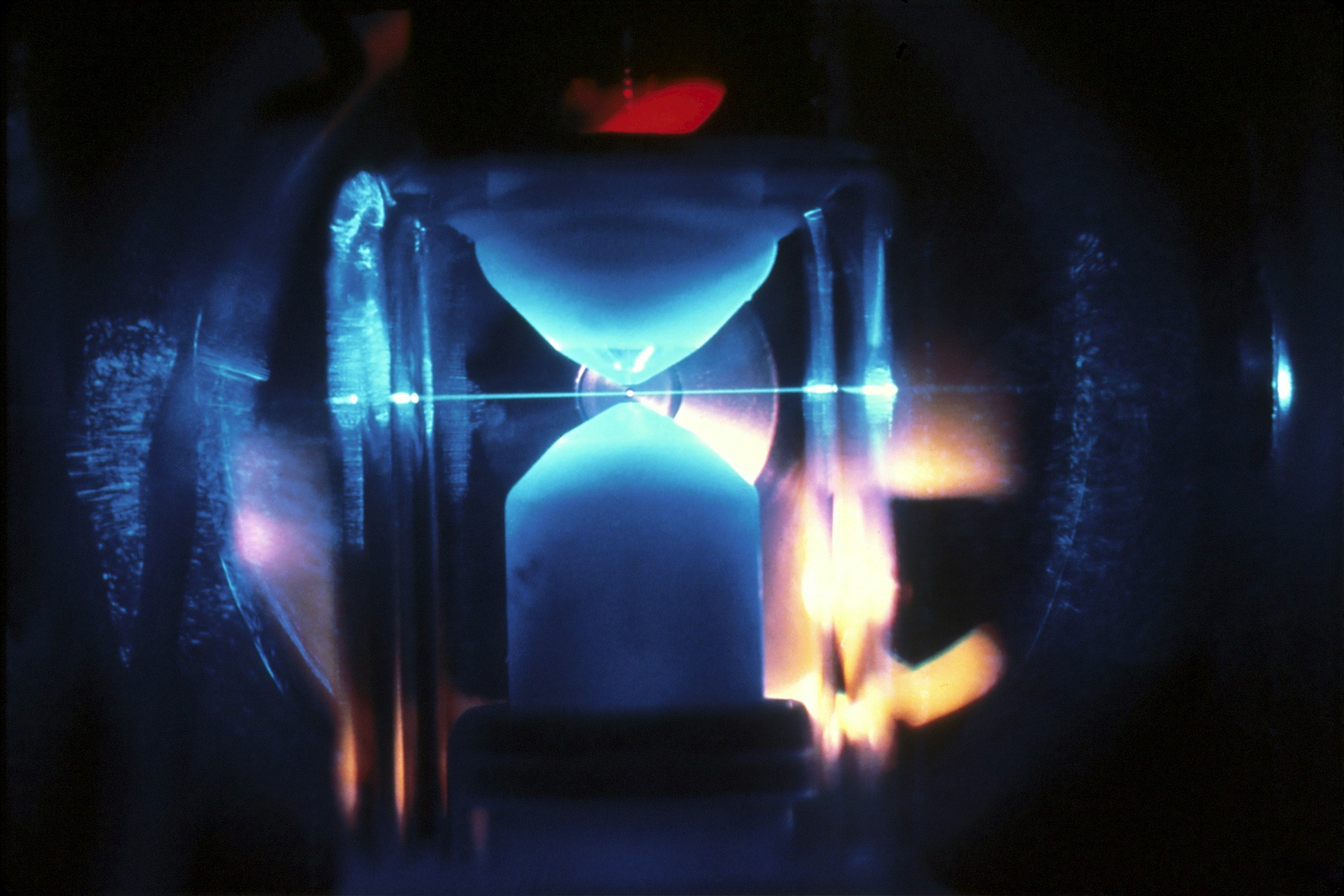

→ REVOLVER 80

360° interior view for full-surface container documentation

Fully rotating camera optics for complete inspection

Illumination through glare-free LED units

Particularly suitable for large pipeline diameters

Minimizes human interpretation through complete image coverage

➕ Your advantages:

Highest image quality & precise verification management, Tamper-proof digital documentation, Time saving in obtaining the reports upon acceptance tests and revisions, Can also be used in ATEX zones or GMP environments

➕ Further special solutions

Our equipment is regularly expanded - including microcameras for tight installation spaces, ATEX-compliant systems and autonomous driving robots for hard-to-reach lines.

→ MATRIX E3 - Control & documentation system

Digital test status control and real-time documentation

Central management of all inspections, release and photo data

Test status tracking for individual components or entire systems

Integration into QA processes or operator documentation systems

Ideal for projects with high documentation pressure or official obligation to provide evidence

→ WBI-Tool - Digital testing of plastic weld seams

Data-based evaluation of thermoplastic compounds

Automatic evaluation of electronic welding records (e.g. barcode, transponder data)

Documentation of parameters such as temperature, pressure, time and error codes

Verification for GMP, FDA, ISO or operator approvals

Particularly relevant in plant engineering for chemicals, semiconductors, ultrapure media

Professional high-end technology that creates trust

Our equipment is not an add-on – it is an integral part of our quality philosophy.